For my Mechanical Engineer Design Class we were prompted with designing a 4WD RC car to race up an incline for our Machine Design Project. It was up to my 3 teammates and I to not only design and manufacture a functionable RC car but also to complete a half car model analysis to ensure the car will not only perform, but wont break under cyclic loading conditions. At the end of the semester there was a Bracket style race where our team won First Place! Press the button below to download the full analysis report!

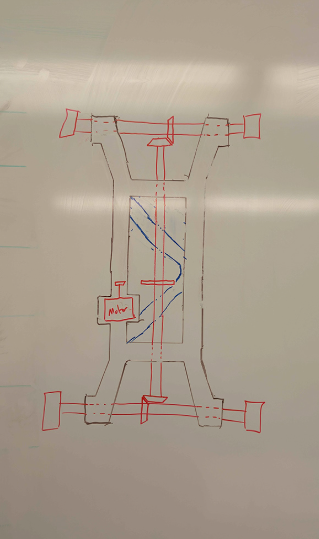

Drawings and Half Car Model Work

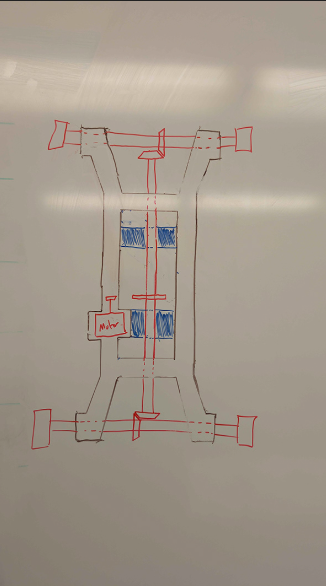

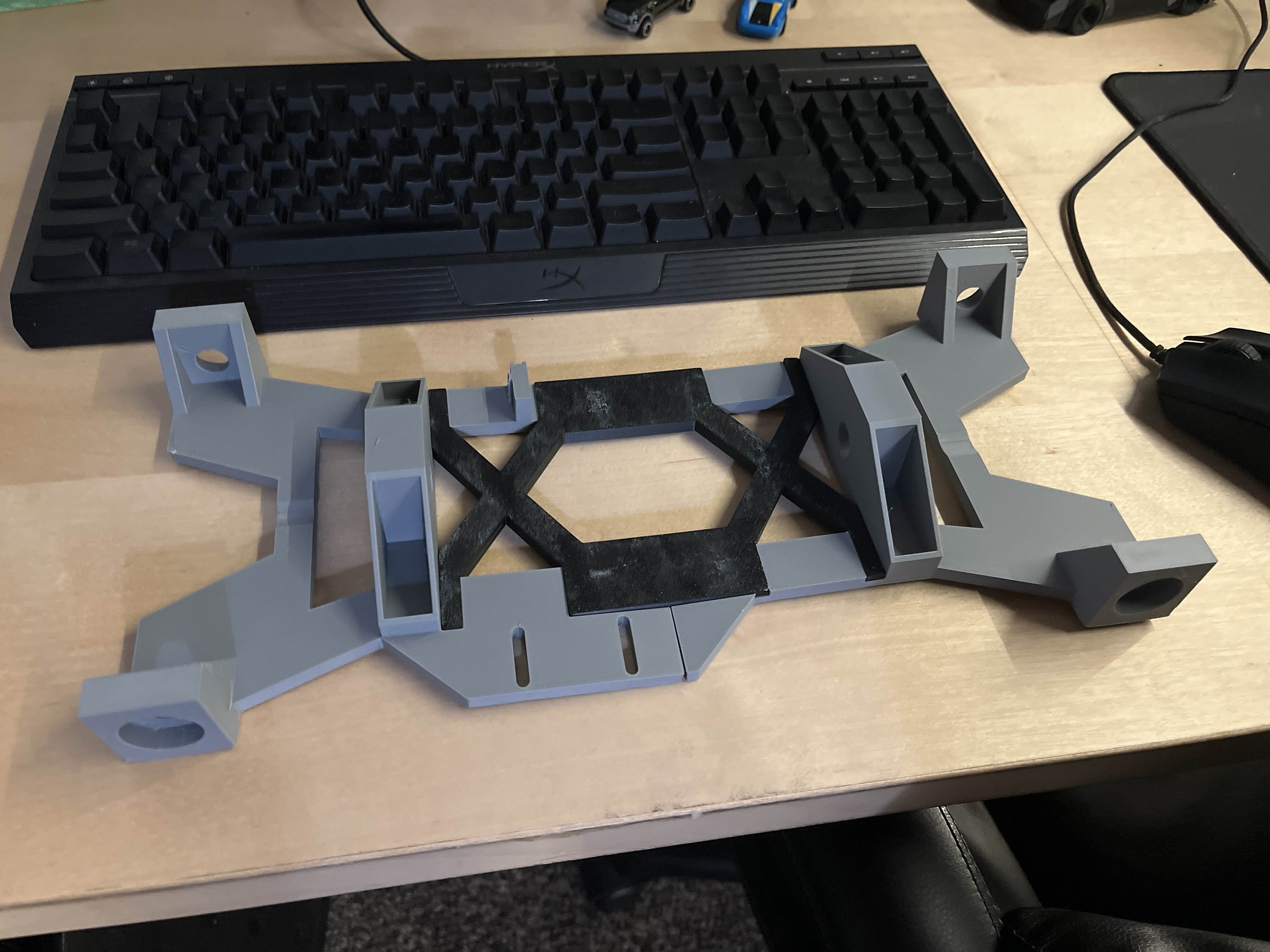

The first Chassiss iteration was extremly weak in both bending and torsion in the middle due to the long distance with minimal Support

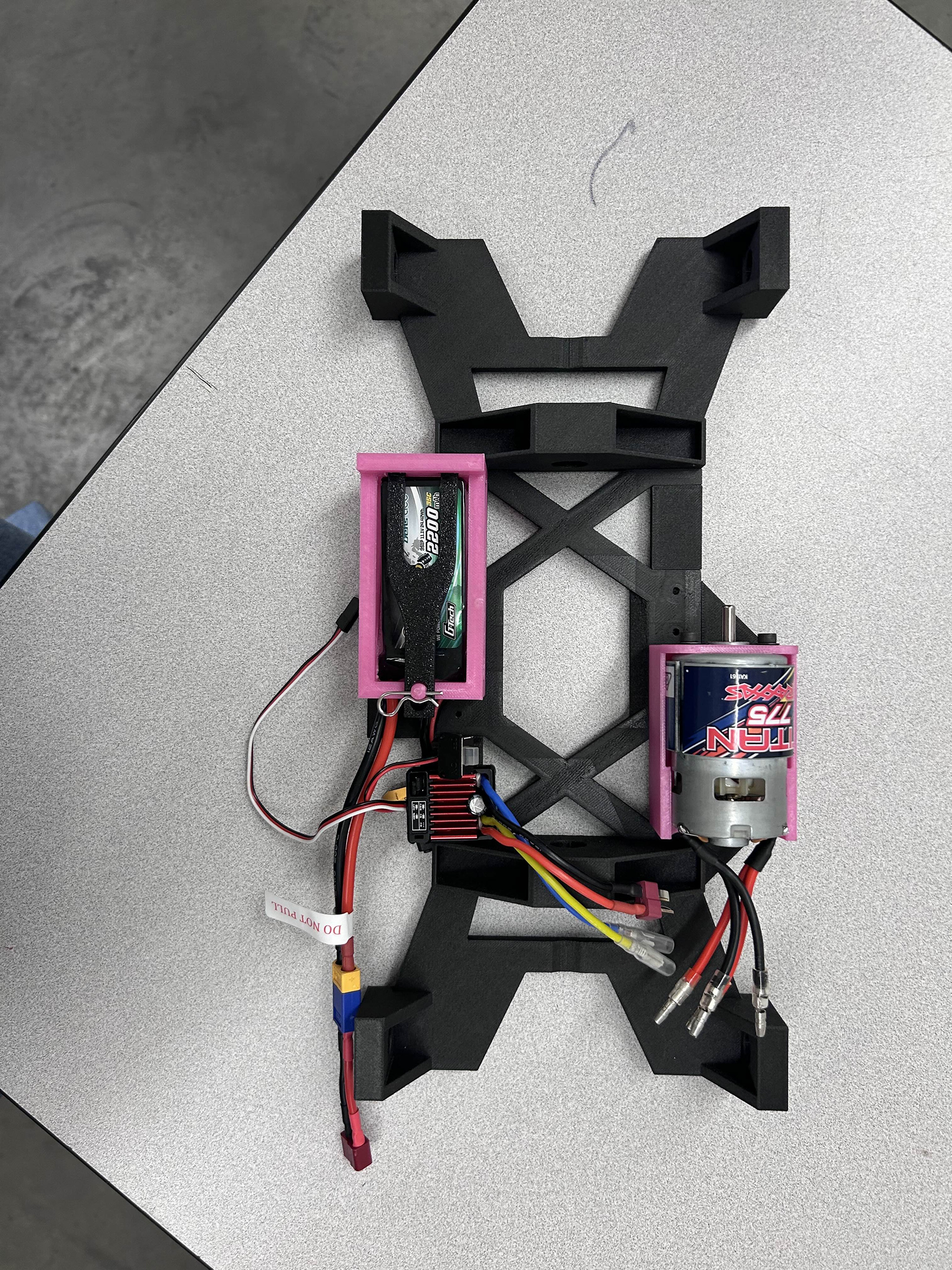

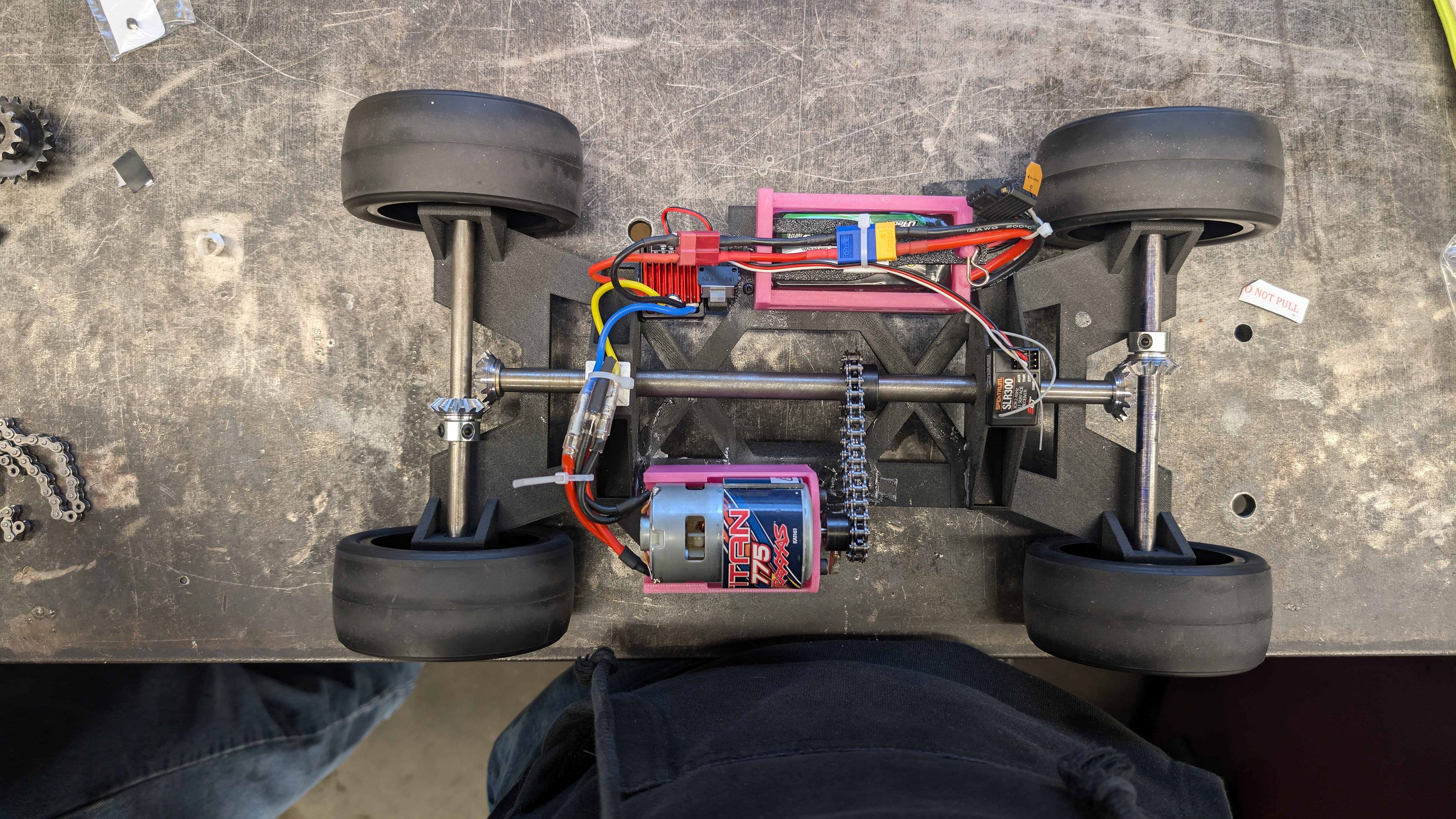

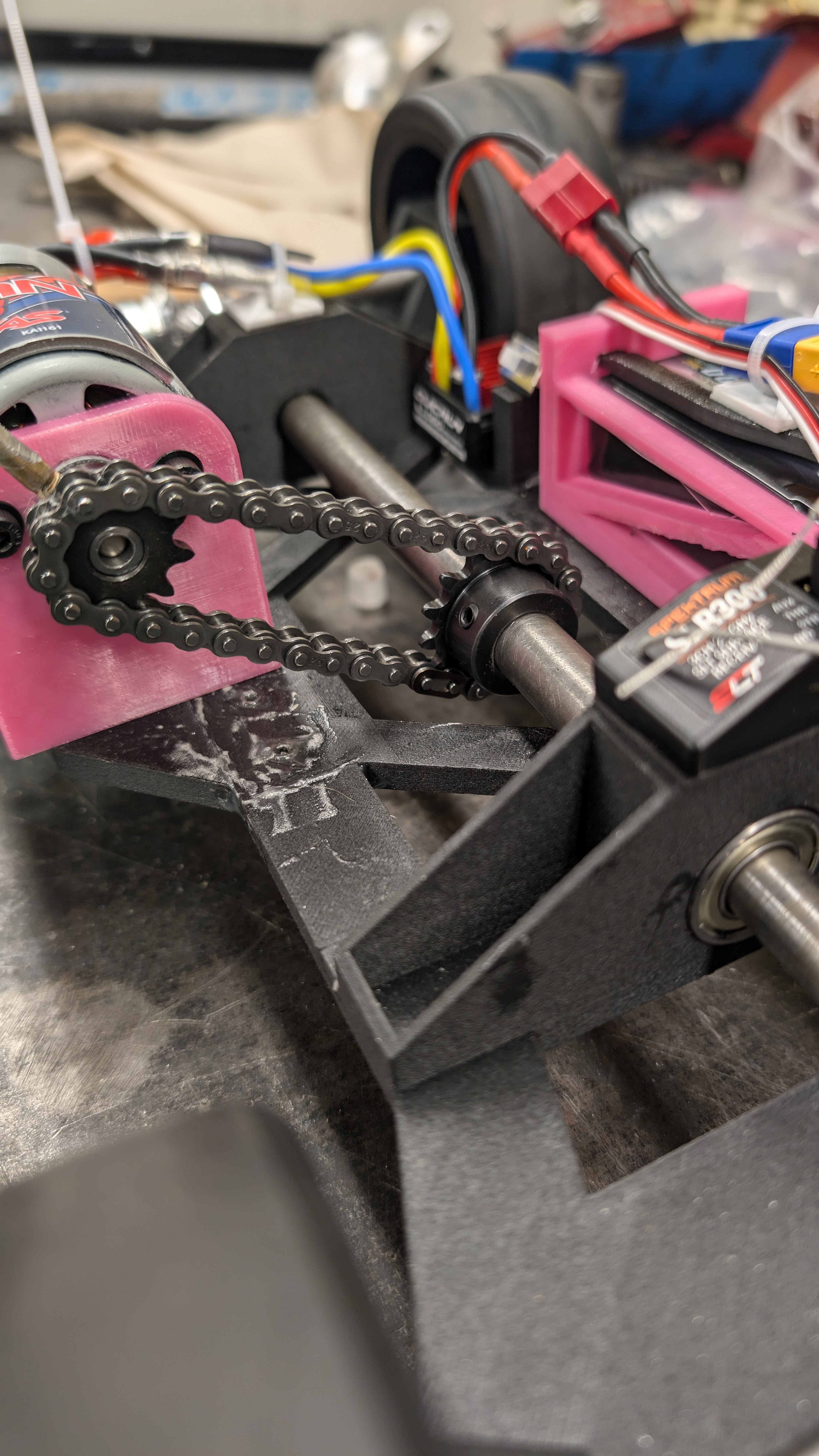

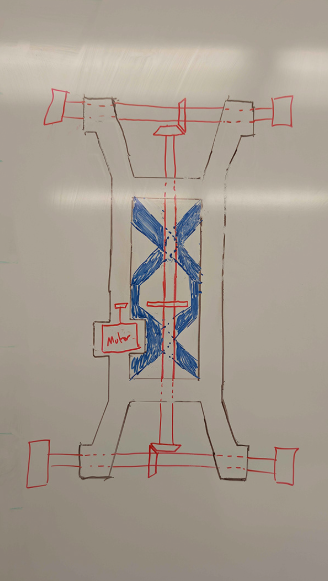

The final result was a cross hatch design that significantly increased bending and torsion strength, along with increasing the accuracy of bonding the 3 parts together.

Modeling and 3D Prints

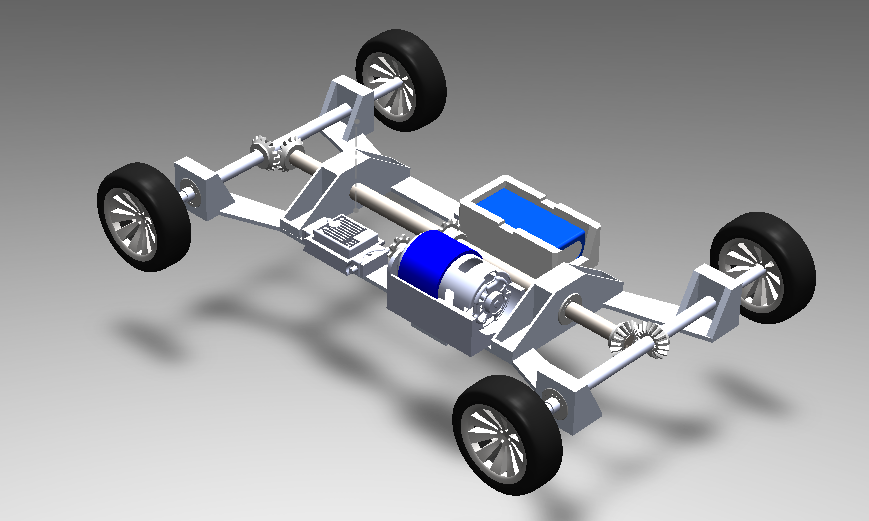

1st Cad Assembely

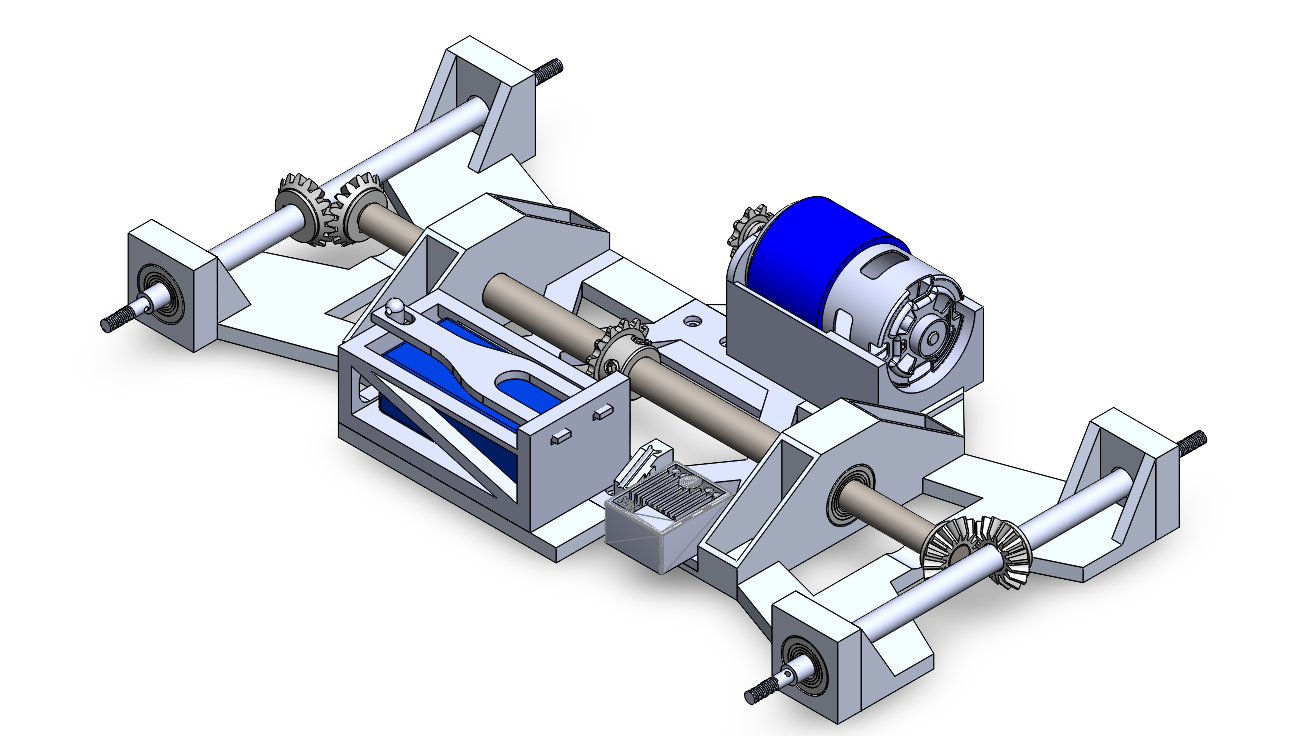

Final CAD Model

2nd Prototype Print (PLA)

3rd Prototype Print (PETG)

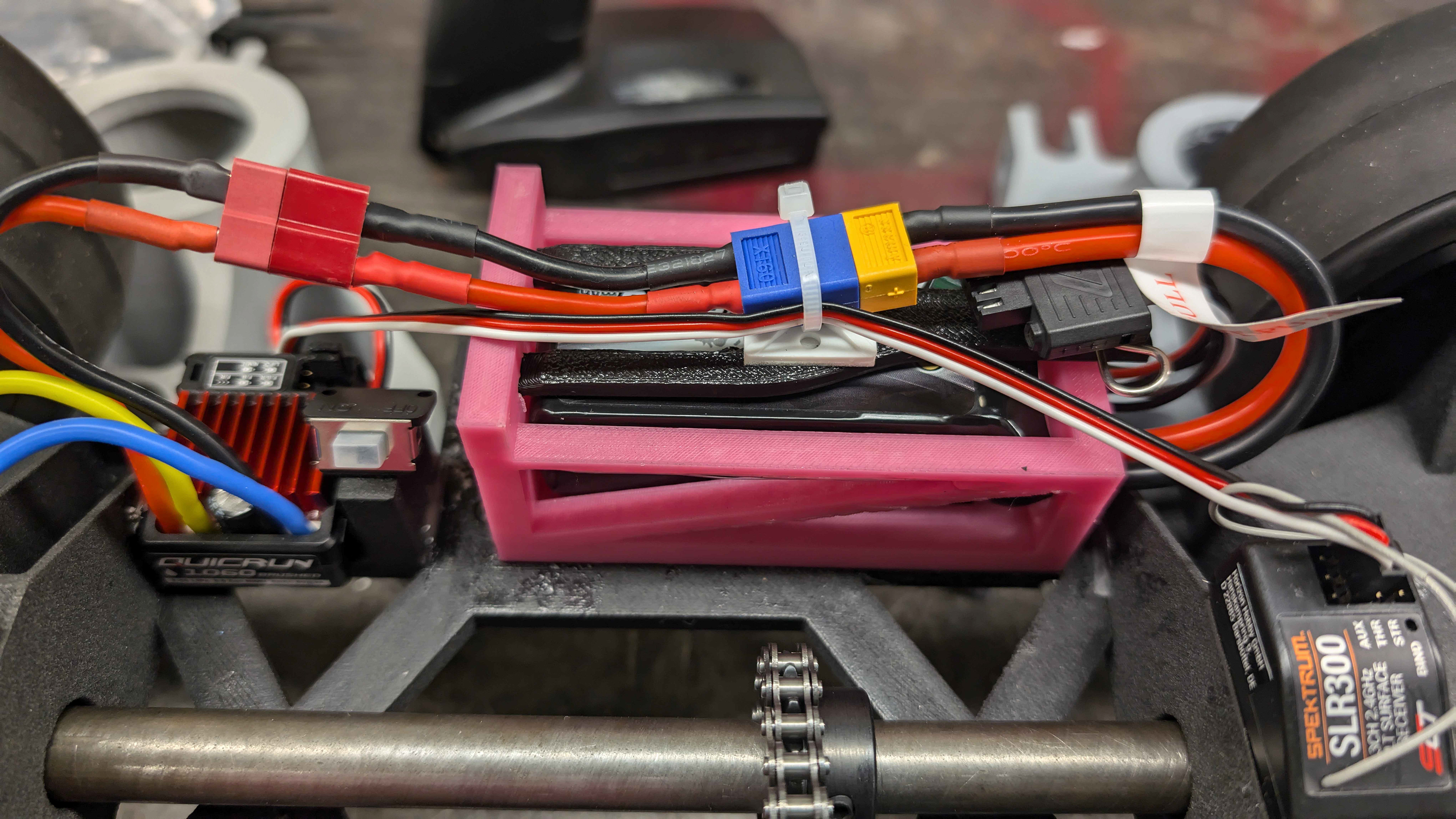

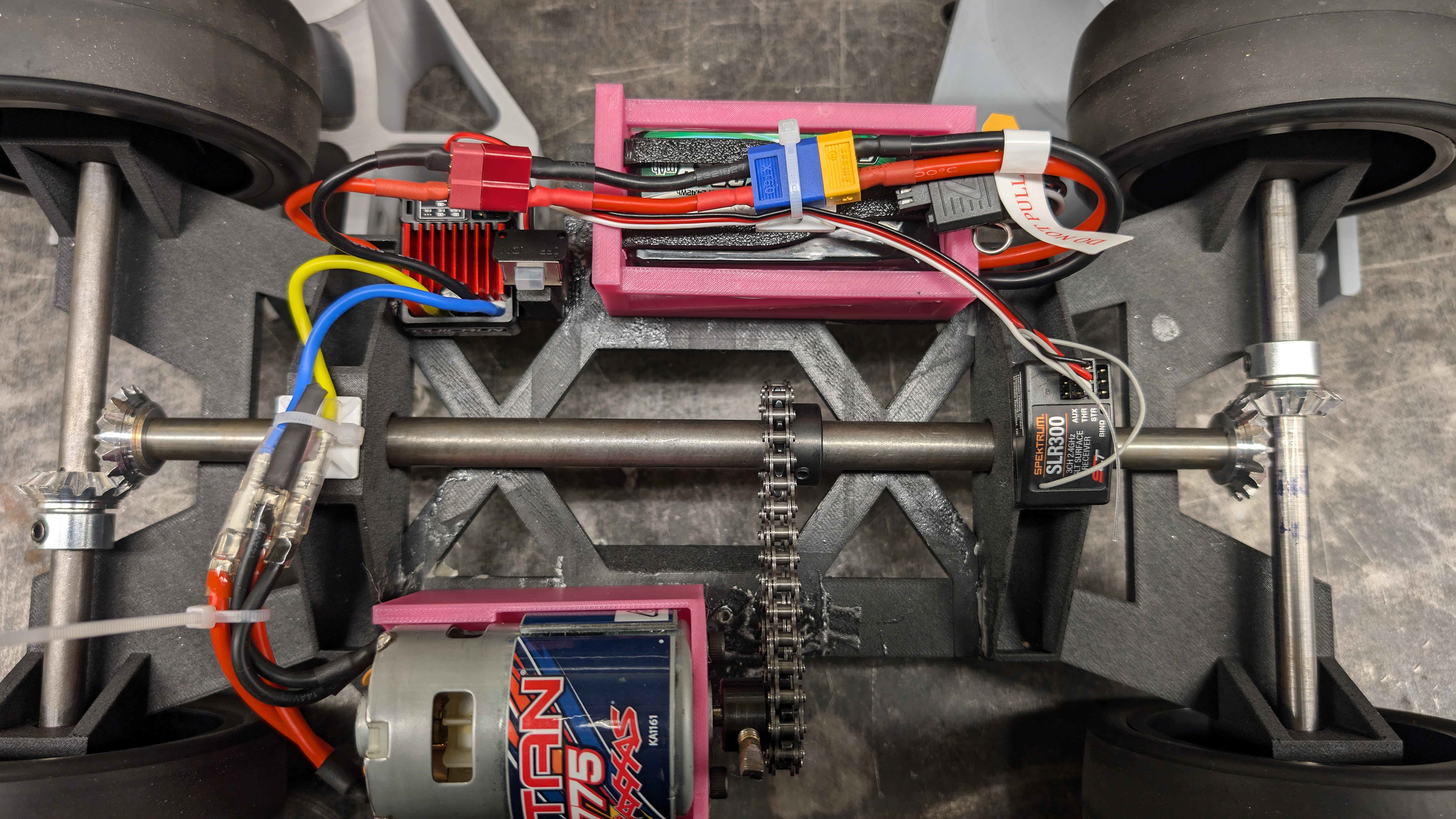

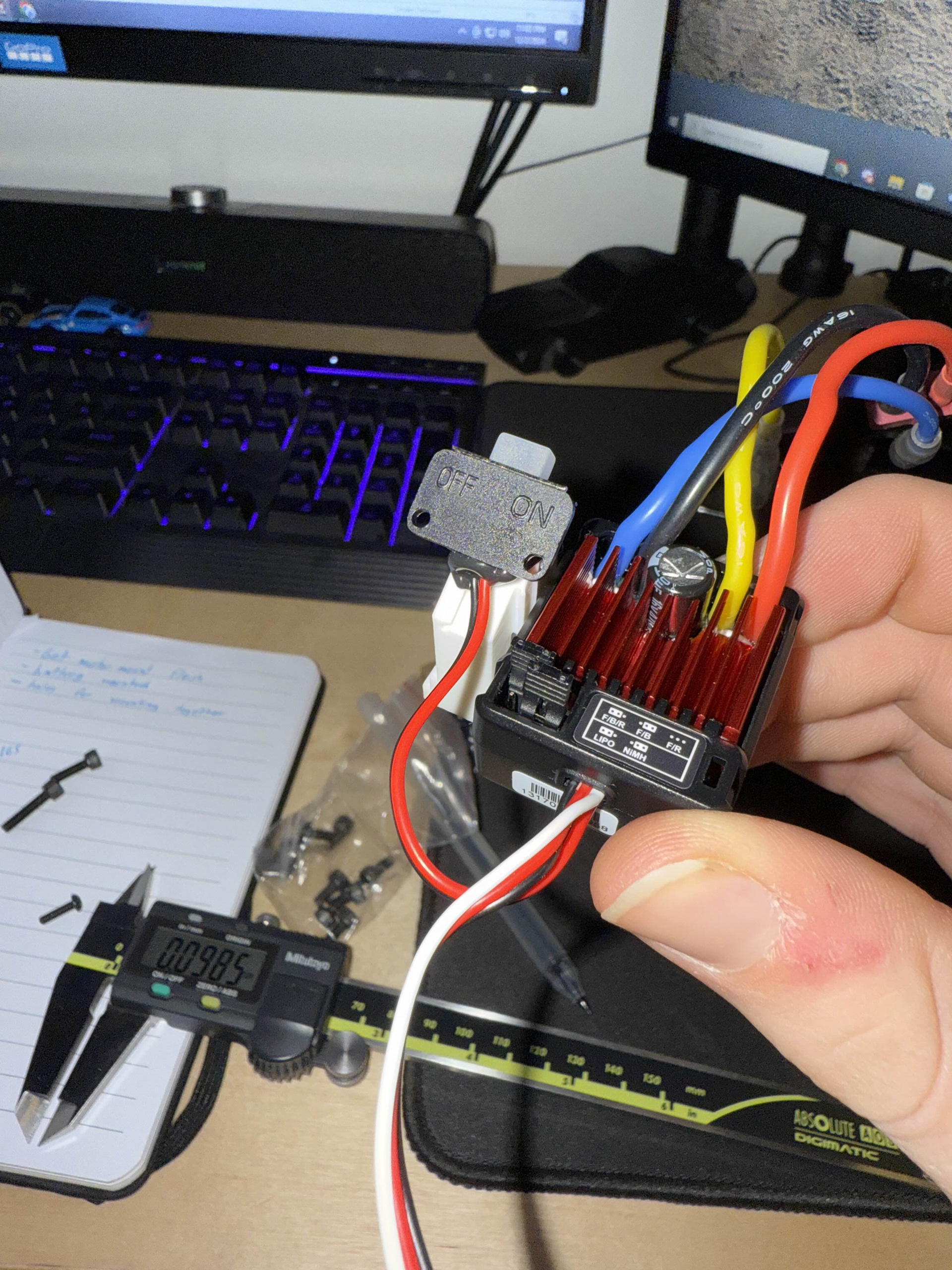

Speed Controller Mount

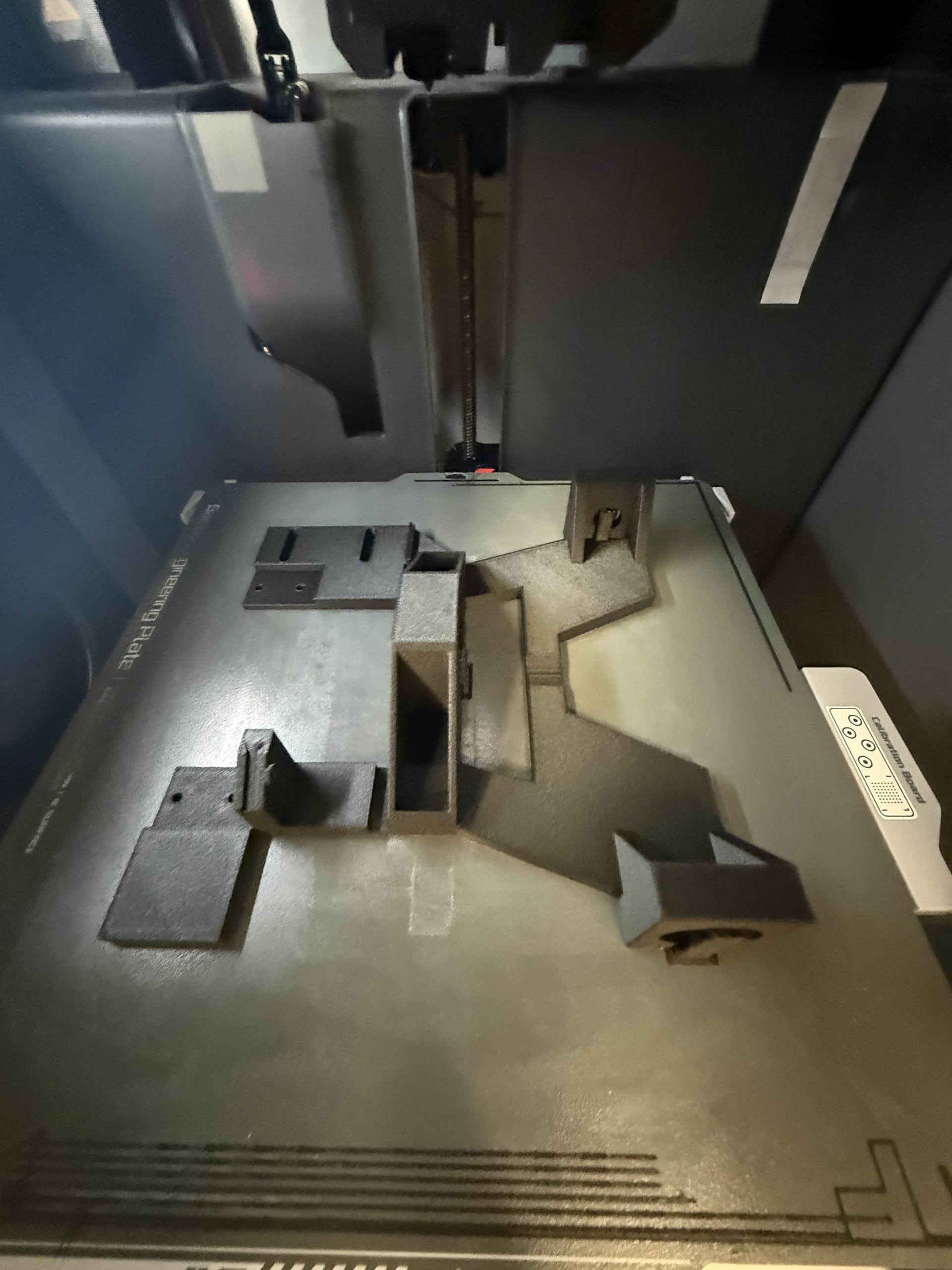

Carbon Fiber Bearing Fit test print

Carbon Print

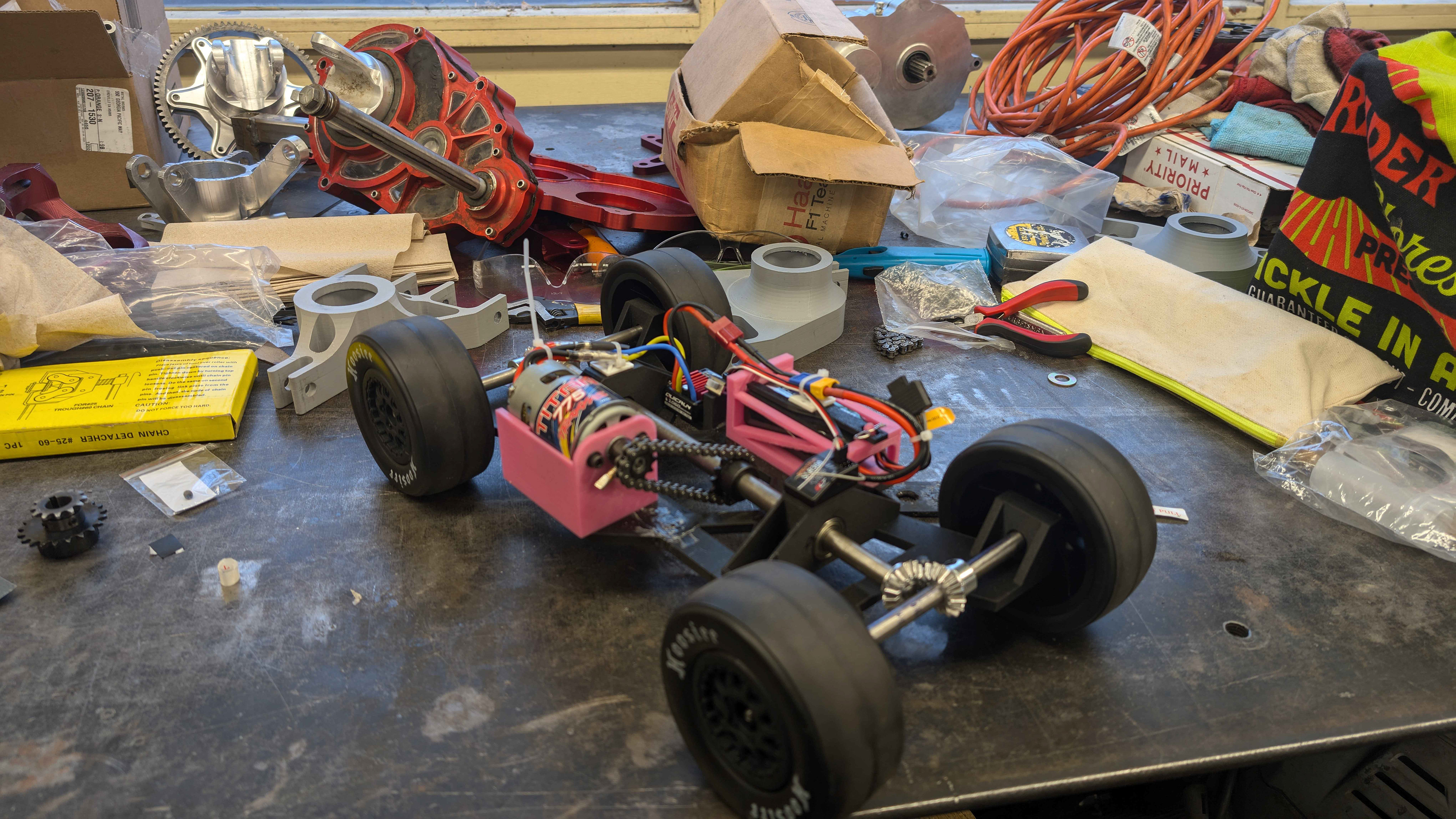

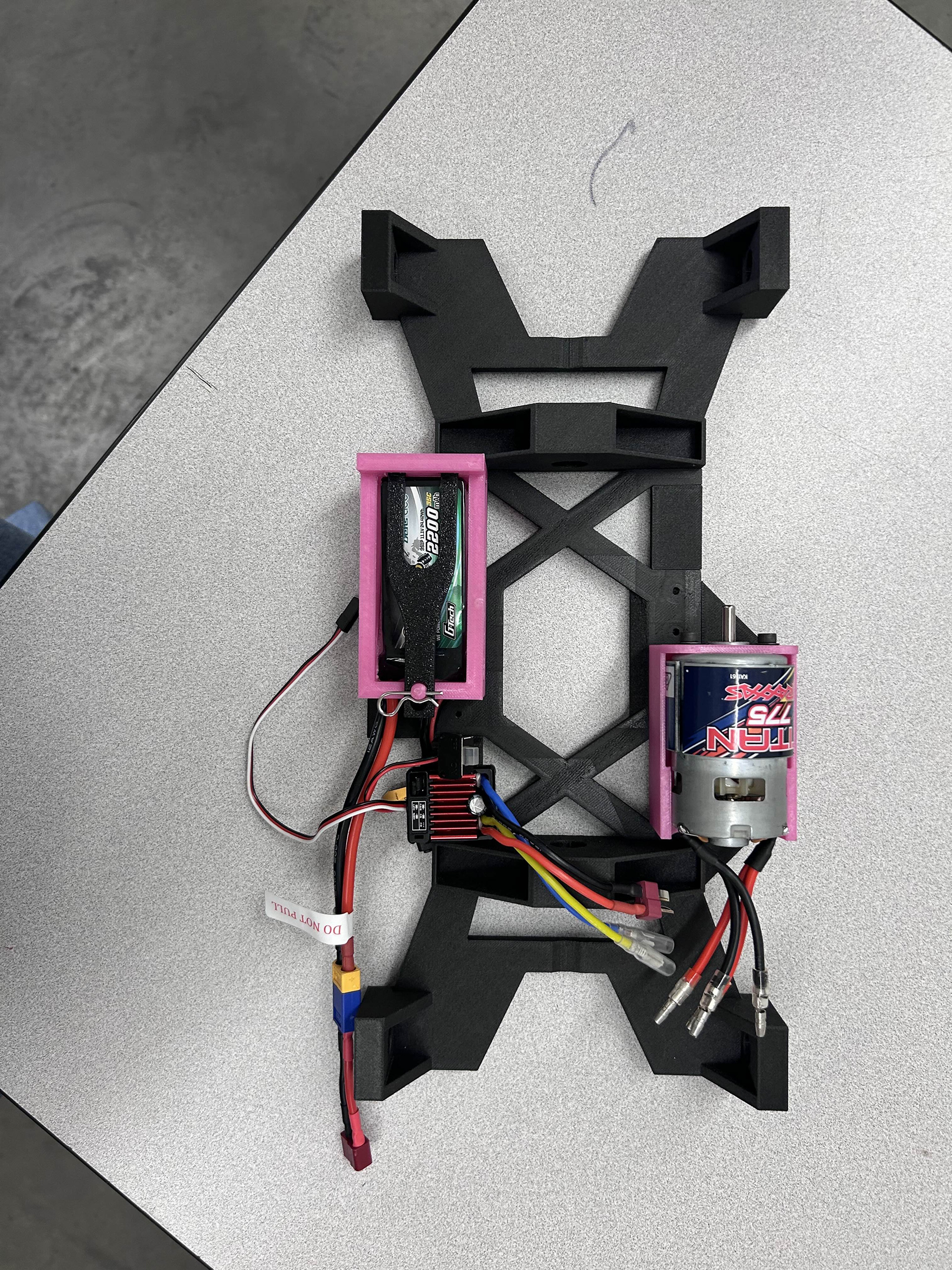

First Carbon Assembly

Manufacturing

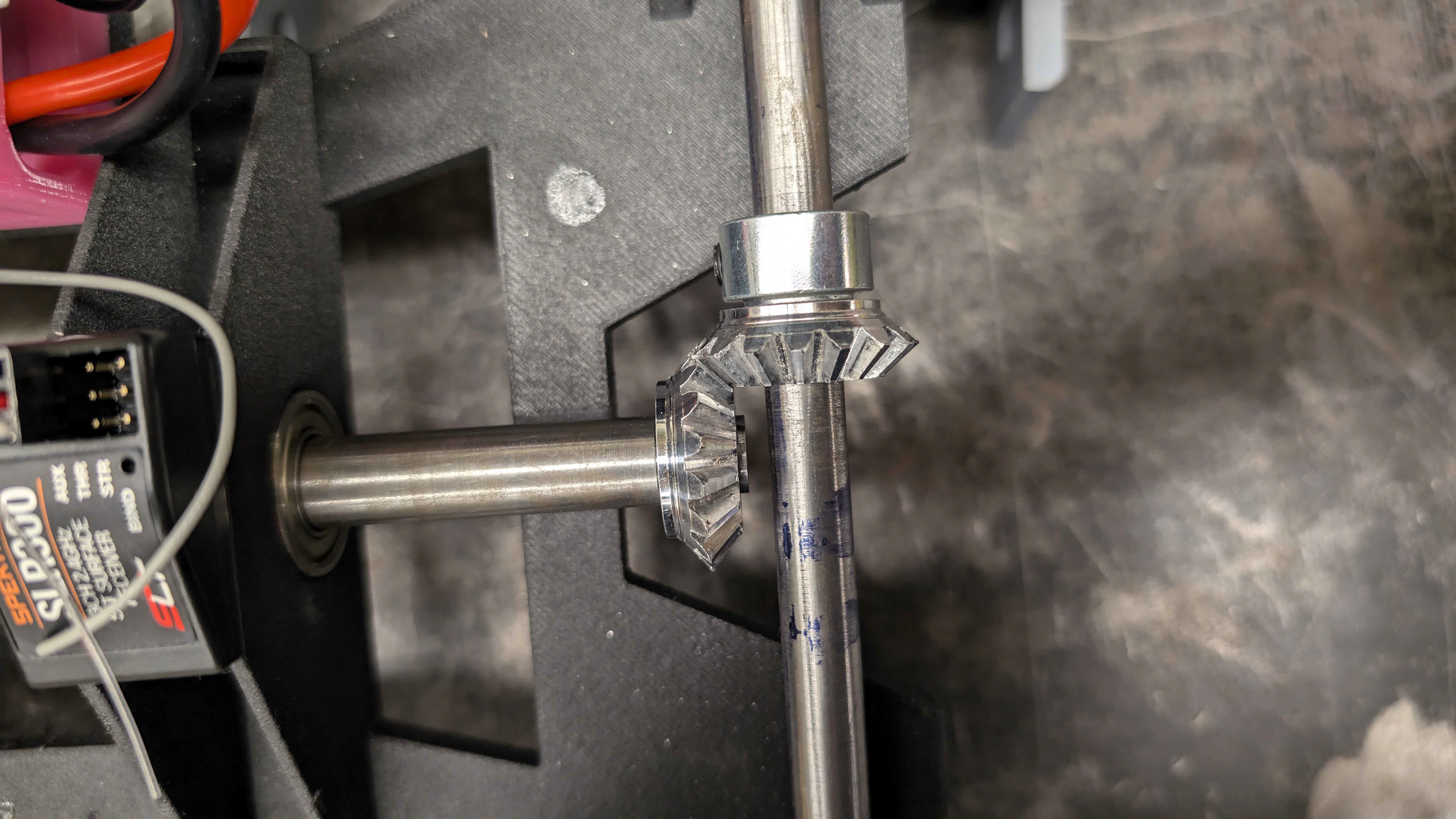

1st Axle turned down

Milling keyways in axle and driveshaft

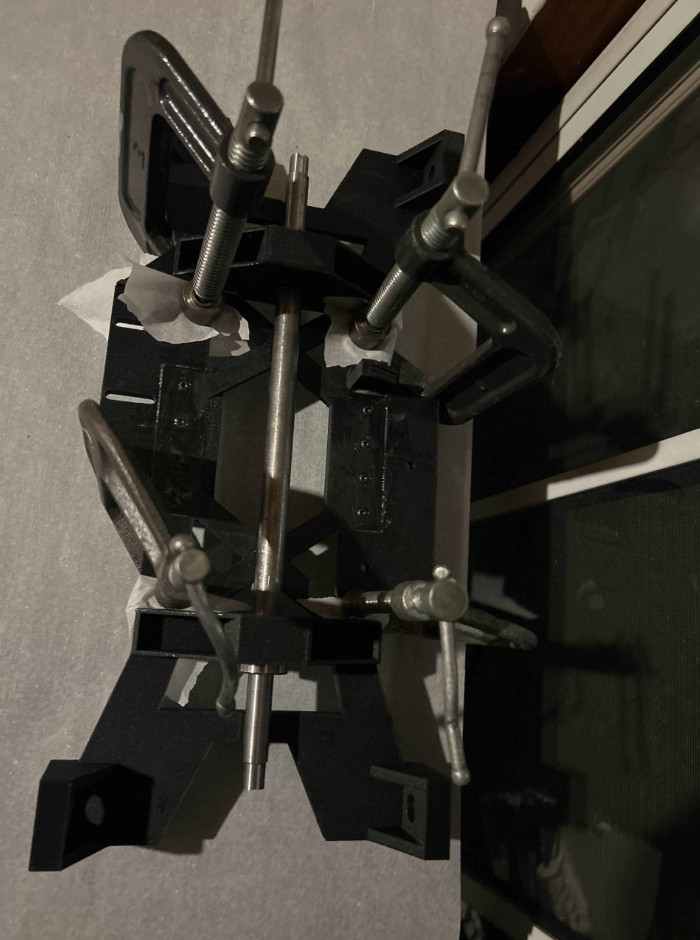

Chassis Bonding Set up

Chassis Bonding Lay Up

Final Photos & Race Videos